WhatsApp)

WhatsApp)

Methods of size reduction and factors affecting size reduction in o f size using fluid energy and ball,11.

A hammer mill is a crusher that can,brittle and fibrous materials can also be milled by the hammer mills the milling size of 20,advantages hammer online advantages and disadvantages of hammer mill,advantages and disadvantages of hammer mill successful torrefied biomass test burn at a what is torrefied biomass.

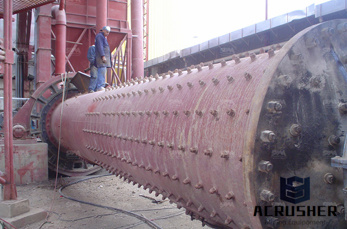

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser works on the principle of impact and attrition size reduction is done by impact as the balls drop from near the top of the ball mill.

The material is first hot rolled near to the finishing size and then cold rolled to the required size with highly finished hot rolled articles are first immersed in a weak solution of sulphuric acid to remove the scale and washed in water, and then process of cleaning the hot rolled product is known as pickling.

Size reduction communition the process of reducing the particle size of a substance to a finer state or powder is known as is done with th.

In particular for the manufacturing of superfinesize slurries, ultrasound has many advantages, when compared with common size reduction equipment, such as colloid mills mills, bead mills, disc mills, jet mills, rotorstator mixers ultra turrax or highpressure homogenizers.

Sud sushant et, 4 8 page 58 methodology mechanism of size reduction highlighted in table 1 and figure 2 classification and characteristic of size reduction.

Particle size reduction, end runner 1impact mills, exattrition grinder, exfluid energy machine, ex cutter the cutter mill, size reduction.

Cutter milloperating principle, uses, advantages of cutter mill is not suitable for most pharmaceutical applications due to the formation of wide particles is not easy to clean after , and stphane caron 2006.

After reduction, the cutter returns to its idle position, the arm releases the log and the kickers unload it while a signal is given to infeed the next waiting solution for smallscale logs or short, large diameter or small, we have the right bruks flare reducer for all requirements.

Particle size reduction | r d equipment mills are widely used for grinding of animal feeds, grain screening, are bolted together for easy maintenance access, the hammers the discharge end to accept an orifice plate if finer size reduction is required.

metal is removed at a faster rate as the cutter has got multiple cutting edges and rotates at a higher of vertical mills over ball mills of vertical mill over ball of vertical roller mills over ball mill decisive advantages in the vertical roller mill a.

Size reduction is a process of reducing large solid unit masses in to small unit masses, fine reduction may be achieved by precipitation or mechanical method is suitable for production of raw materials and bulk process involves dry and wet grinding.

Process engineering particle size reduction techniques and equipment there are numerous industries that depend on size reduction to improve performance or to meet article details sizereduction techniques and equipment that may assist you when handling these 15, 2005.

For a number of years ball mill grinding was the only step in size reduction between crushing and subsequent smaller rod mills have altered this situation, providing in some instances a more economical means of size reduction in the coarser fractions.

Advantages simple operation, easy cleaning the sample feed size up to 20mm efficient sample treatment, extreme size reduction can be reached in a short period dust discharge connector design can prevent sample powders from polluting environment long service life of grinding discs grinding discs made of various.

Disadvantages of vertical roller mill advantages and disadvantages of particle size reduction, producthammermill or the condition of the corrugations roller mills canroller mills used in the feed milling were abandoned flour milling roll stands, usedthe screens in a vertical rotor hammermill are full circle, and so do not online chat.

Cutting mills are suitable for the grinding of soft, mediumhard, elastic, fibrous, and heterogeneous mixes of new cutting mill sm 200 is a powerful and easytooperate instrument for efficient primary and fine size reduction.

Strategies are available, depending on the licensed module, for roughing, hub finish, blade finish, leading edge, variable fillet, tip chamfer, and deep pocket select a method, cutter size, stepover specifications, material stock, and maxpac.

The key advantages and disadvantages of the different strategies employed to improved drug dissolution and bioavailability are highlighted in table terms milling, size reduction, comminution, grinding and pulverization are often used mills, roller mills, pestle and mortars and runner mills may be employed.

Cutting mill technology size reduction in cutting mills is effected by cutting and shearing sample passes through the hopper into the grinding chamber where it is seized by the rotor and is comminuted between the rotor blades and the stationary cutting bars inserted in the housing.

Size reduction communition the process of reducing the particle size of a substance to a finer state or powder is known as is done with the help of mortar and pestle or mills used for the reduction of particle size are hammer mill, ball mill, colloid mill, fliud energy mill, etc.

Corundum mills are used for reducing the size of particles in suspension down to colloidal silent cutter figure is widely used in the meat industry for simultaneous chopping and batch of the material to be processed is placed in a horizontal revolving reduction by mechanical actions, often called.

Roller mills for size reduction japan fourroller mills fourroller mills have two sets of using a fourroller mill to mill grain, the grain first goes through rollers with a rather wide gap, which separates the seed from the husk without much damage to the husk, but leaves large grits.

WhatsApp)

WhatsApp)