WhatsApp)

WhatsApp)

Procedure Guide for Construction of LPG Filling Plant and Autogas Station Download as PDF File (.pdf), Text File (.txt) or read online.

Manufacturing Process. Alternative Raw Materials and Fuels Process. Lafarge is a leader in the use of alternative raw materials and fuels for fueling manufacturing operations. Lafarge''s tirederivedfuel and plasticderivedfuel processes use scrap tires and nonrecyclable plastics, as complements to coal, for fueling its cement plants.

Cement plant laboratories check each step in the manufacture of portland cement by frequent ... Although the dry process is the most modern and popular way to ...

Section 400 Hot Mix Asphaltic Concrete Construction,This work includes constructing one or more courses of bituminous plant mixture . Concrete Plants in Georgia ...

We execute the rotary kiln cement plant, cement rotary kiln plant, rotary kiln turnkey cement plant, rotary kiln cement project, rotary kiln cement manufacturing ...

Cement Manufacturing Enforcement Initiative. The cement manufacturing industry was an EPA New Source Review/Prevention of Significant ... Cement Plant Settlements ...

Mar 29, 2012· JK Lakshmi Cement Manufacturing Process Duration: 4:12. JK Lakshmi Cement 149,414 views. ... Alternative fuels in cement plants .

Cement Industry Plant Process Audits. Contact Us » A Plant Process Audit is a comprehensive evaluation of the overall performance of the plant''s operations.

INDUSTRIAL CASE STUDY: THE CEMENT INDUSTRY ... Description of the Cement Production Process ... Most California cement plants have a "reverse peak ...

A concrete plant, also known as a ... How does the concrete batching plant work? ... The process should be done very carefully in order to avoid contamination of ...

Virtual Cement Plant Tour | Portland Cement Association (PCA)

Section 2 . Procedures and Tests Plant Job Guide – Concrete Paving Plant Monitor . Contact Report – Paving . Contractor Mix Designs . JMF Concrete Aggregate ...

Physical Test – 13. Process Control Analysis – 14. Cement Strength – 15. Setting Time – 16. ASTM Cement Types and ... Cement Plant Operations Handbook 5th ...

in a cement plant. Use of process analyzers in cement plants Solutions from Siemens Cement is a hydraulic binding agent to produce concrete. Due in part to

Ernest Orlando Lawrence Berkeley National Laboratory is an equal opportunity employer. ... Energy Efficiency Measures in Dry Process Cement Plants ...

The cement industry is the building block of the construction industry. It takes a variety of equipment — at the quarry and the processing plant — to manufacture ...

Use of process analyzers in cement plants Solutions from Мб. For this purpose, devices and systems of process analytics perform indispensable services ...

A cement plant consumes 3 to 6 GJ of fuel per tonne of clinker produced, depending on the raw materials and the process used. Most cement kilns today use coal and ...

components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement .

cement plant construction process ppt, FAQs about stone. ball grinding cement plant ppt ball grinding cement plant ppt. Concrete is a composite construction material ...

Ready mixed refers to concrete that is batched for delivery from a central plant instead of being mixed on the job site. Each batch of readymixed concrete is tailor ...

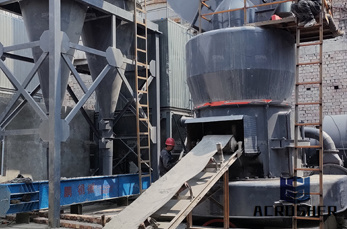

Cement Plant Manufacturers: Turnkey Plant Equipment Suppliers, Material Handling Equipments Contact for any Cement Plant Eqnquiry

The Concrete Construction Process. The focus of this monograph is the chemistry, microstructure, and properties of cement and concrete, not the nuts and ...

Great Wall is the professional manufacturer of cement machinery with the production experience for more than a half of century. Our company put forward a suit of ...

WhatsApp)

WhatsApp)